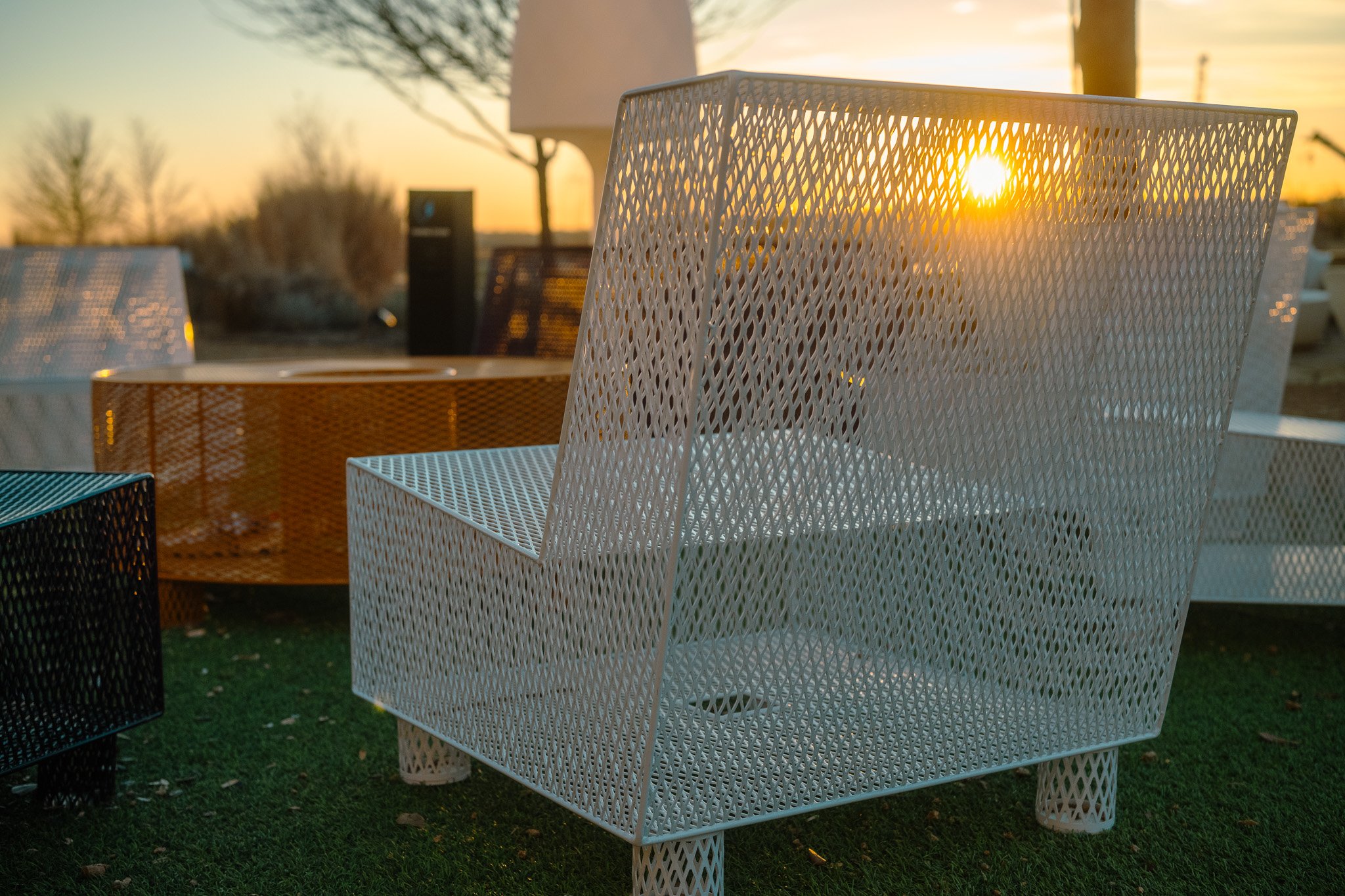

Half13 is a collection of outdoor stainless steel furniture designed by Damian Velasquez circa 2008.

The entire furniture line is constructed from the industrial material called expanded metal. Stainless steel sheet metal is slit with large industrial equipment to expanded into a mesh like material. The openings are distinctly diamond shaped. This material is not rigid on its own. Damian’s unique approach to building with this material is based on using a rigid frame of stainless steel rod that allows the panels to interlock and become rigid when welded together.

After receiving a large pallet of stainless steel sheet from our Oklahoma USA based supplier, we begin processing the flat sheets. The sheets require initial cutting via CNC plasma. They are then de-burred and washed.

Although it may appear to be a uniform material, there is often variation in the cut edge and remaining tension within the parts. Rolling the freshly cut panels removes tension and makes the fixturing process much more efficient.

At this stage the stainless rod is also rolled into subtle curves for arms or complete circles for the round table tops. These preliminary steps must be taken to ensure the final chair or table is welded together symmetrically with no excess tension in the panels.